1. Skład Materiału

| Gatunek |

Oznaczenie UNS |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Inne |

| T5 |

K41545 |

0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.5 |

4.0–6.0 |

... |

0.45-0.65 |

... |

2. Norma: ASTM A213

Niniejsza norma dotyczy bezszwowych rur ze stali ferrytycznej i austenitycznej do kotłów, przegrzewaczy i wymienników ciepła, przeznaczonych do pracy w wysokich temperaturach pod ciśnieniem.

Gatunek: T5

Oznacza to konkretny skład stali stopowej chromowo-molibdenowej (Cr-Mo).

3. Rodzaj Materiału: Stal niskostopowa

Wyróżnia się ją od stali węglowych i stali nierdzewnych (gatunki austenityczne, takie jak 304, 316, są również objęte normą ASTM A213, ale mają inne oznaczenia gatunków, takie jak TP304, TP316).

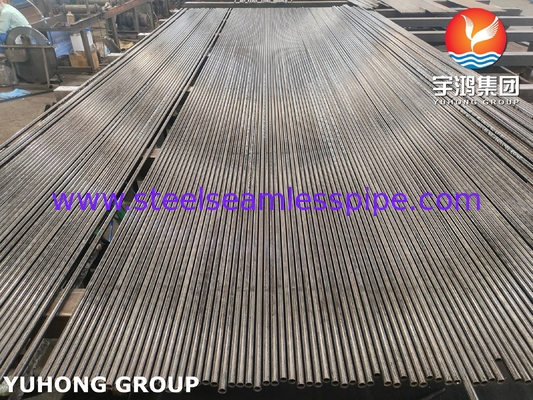

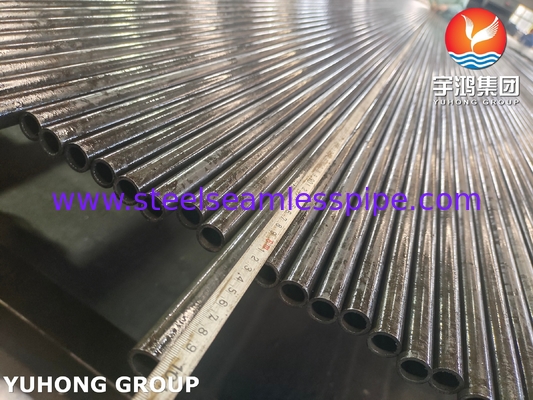

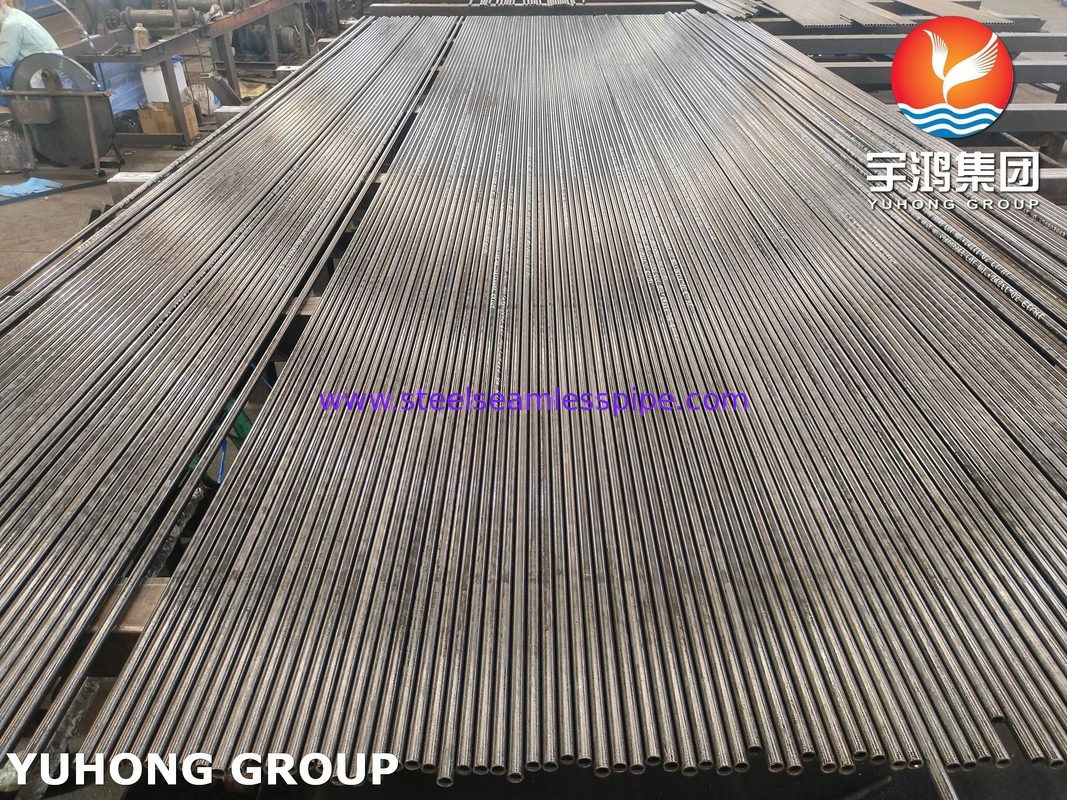

4. Produkcja bezszwowa:

Rury są produkowane bez spoiny, zazwyczaj w procesach takich jak wytłaczanie, przebijanie obrotowe (proces Mannesmanna) lub walcowanie na pielgrzymce. Zapewnia to:

Wyższą wytrzymałość i integralność: Brak słabego punktu w postaci spoiny.

Lepsze utrzymywanie ciśnienia: Niezbędne w zastosowaniach kotłowych i ciśnieniowych.

Jednolitość: Bardziej spójna struktura i właściwości na całym obwodzie.

Lepsza odporność na korozję/erozję: Brak spoiny podatnej na preferencyjny atak.

5. Kluczowe właściwości i dlaczego stosuje się T5:

Dobra wytrzymałość w wysokich temperaturach (wytrzymałość na pełzanie): Dobrze zachowuje wytrzymałość w temperaturach powszechnie spotykanych w kotłach i przegrzewaczach (zazwyczaj do ~650°C / 1200°F w przypadku długotrwałej eksploatacji, chociaż dokładne limity zależą od naprężeń). Molibden jest tutaj kluczowy.

Dobra odporność na utlenianie: Chrom tworzy ochronną warstwę tlenkową, odporną na degradację przez gorące gazy spalinowe.

Dobra odporność na siarkowanie: Sprawdza się lepiej niż stale o niższej zawartości stopu (takie jak T11/T12) w środowiskach zawierających związki siarki.

Umiarkowana odporność na korozję: Lepsza niż stal węglowa, ale gorsza niż stale nierdzewne.

Spawalność: Ogólnie uważana za spawalną z odpowiednim podgrzewaniem wstępnym, obróbką cieplną po spawaniu (PWHT - odprężanie) i procedurami (powszechne procesy obejmują GTAW, SMAW, SAW). PWHT jest krytyczne dla przywrócenia właściwości i odciążenia naprężeń w strefie wpływu ciepła (HAZ).

6. Typowe zastosowania:

Stosowana głównie w wysokotemperaturowych, wysokociśnieniowych sekcjach:

Elektrownie opalane paliwami kopalnymi:

Rury kotłowe (szczególnie w strefach o wyższej temperaturze)

Rury przegrzewaczy

Rury do ponownego podgrzewania

Wymienniki ciepła: W zakładach chemicznych/petrochemicznych, gdzie temperatury robocze wymagają lepszej wytrzymałości niż stal węglowa, ale pełna stal nierdzewna nie jest konieczna.

Rurociągi i urządzenia w rafineriach: Do specyficznych strumieni procesowych o wysokiej temperaturze.

Zbiorniki ciśnieniowe: Komponenty pracujące w podwyższonych temperaturach.

7. Obróbka cieplna (zgodnie z ASTM A213):

Rury T5 są dostarczane w stanie odprężonym.

Odprężanie polega na podgrzaniu rur do temperatury poniżej dolnej krytycznej temperatury przemiany (Ac1), utrzymaniu i powolnym chłodzeniu. Powoduje to odciążenie naprężeń wewnętrznych powstałych podczas produkcji bez istotnej zmiany mikrostruktury (ferryt + węglik).

Uwaga: Inne gatunki Cr-Mo, takie jak T91, wymagają normalizacji i hartowania, ale T5 jest specyficznie odprężany.

8. Badania i inspekcja (zgodnie z ASTM A213):

Próba hydrostatyczna: Każda rura jest testowana ciśnieniowo.

Nieniszcząca próba elektryczna (NDE): Każda rura przechodzi test elektromagnetyczny (np. prąd wirowy) w celu wykrycia istotnych wad podłużnych.

Próba spłaszczania, próba twardości, próba spłaszczania odwrotnego: Przeprowadzana na próbkach z partii.

Próba rozciągania: Określa właściwości mechaniczne (granica plastyczności, wytrzymałość na rozciąganie, wydłużenie) na próbkach z materiału poddanego obróbce cieplnej.

Analiza chemiczna: Na wytop (partia stali).

Wymiary i kontrola wizualna: Średnica zewnętrzna, grubość ścianki, prostoliniowość, jakość powierzchni.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!