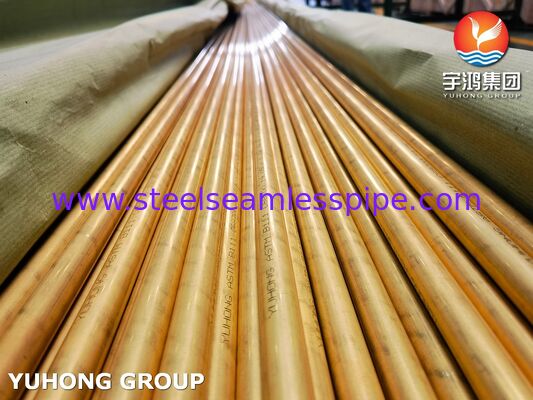

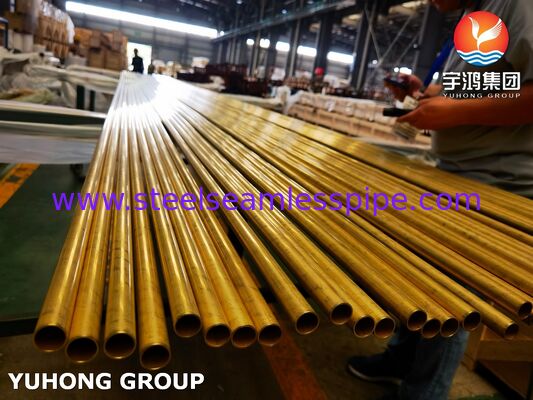

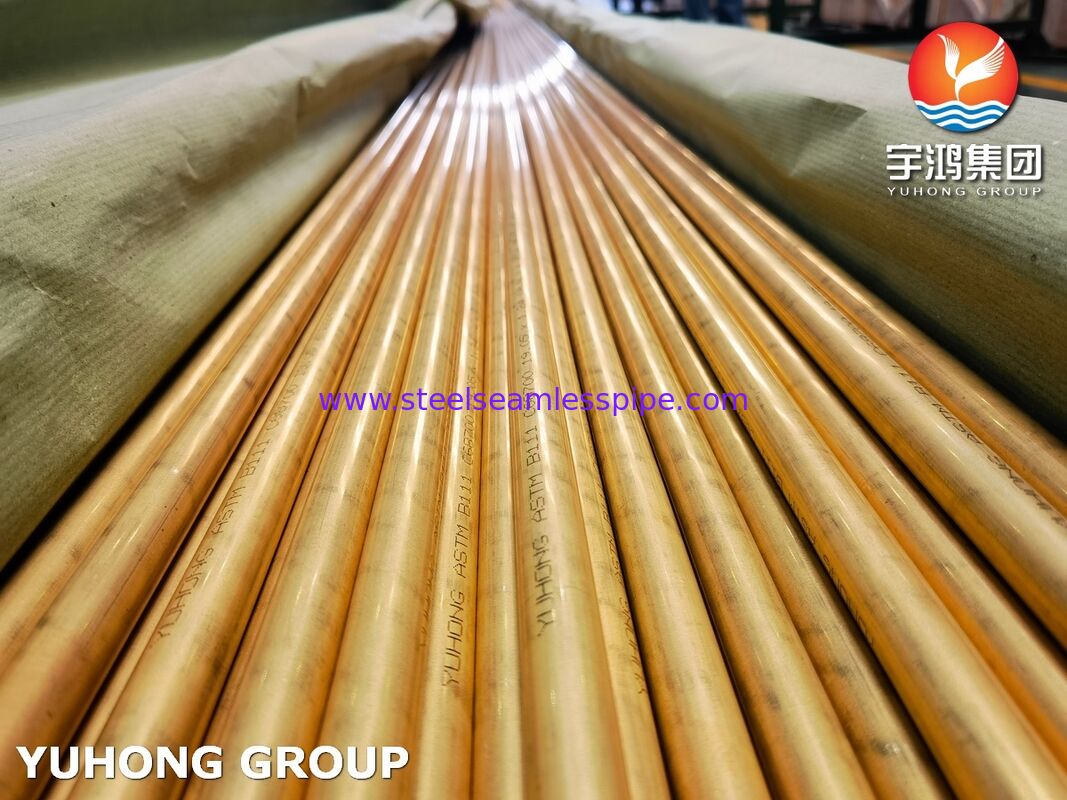

COPPER ALLOY SEAMLESS TUBE ASTM B111 C68700 O61 ALUMINUM BRASS B

C68700 is a brass alloy (copper-zinc base) with two key additive elements:

Aluminum (Al): Typically 1.8-2.5%. This is the primary addition that gives the alloy its most important property.

Arsenic (As): A small addition (0.02-0.06%) to prevent dezincification corrosion.

The standardized composition makes it part of the "UNS C68700" designation (Unified Numbering System).

Primary Application: It is almost exclusively used for heat exchanger and condenser tubes, especially in environments where resistance to saltwater corrosion is critical.

C68700 Tube Chemical Composition

| Element |

Weight % |

| Copper |

76.0-79.0 |

| Zinc |

Reminder |

| Aluminium |

1.8-2.5 |

| Arsenic |

0.02-0.06 |

| Lead |

0.07 |

| Iron |

0.06 max |

|

Dimensional Range

Outer Diameter - 4.00 to 22.00 mm

Wall Thickness - Between 0.15mm and 1.50 mm

Length upto 6 mtrs

End Applications

Heat Exchangers, Oil Coolers, Radiators, High Capacity Power Plants, Ship Building & Ship Repairs, Condensers, Offshore Oil rigs, Distiller Tubes, Evaporators, Ferrules etc.

Key Advantages of C68700 (Arsenical Aluminum Brass)

The advantages stem directly from its aluminum content and its stable, protective surface film.

1. Superior Corrosion Resistance (Especially to Impingement Attack)

Formation of a Protective Film: When exposed to water (particularly seawater), the aluminum in the alloy reacts to form a thin, tenacious, and self-healing layer of aluminum oxide (Al₂O₃) on the tube's inner surface. This film is extremely hard and adherent.

Resists High-Velocity Water: This aluminum oxide film provides exceptional resistance to impingement attack (also called "erosion-corrosion"). This is the wear caused by fast-moving, turbulent, or air-bubbly water, which can quickly destroy ordinary copper alloys. This makes C68700 the premium choice for saltwater service in marine condensers and offshore platforms.

2. Excellent Biofouling Resistance

The protective aluminum oxide film creates a surface that is less hospitable for marine organisms (like barnacles, mussels, and algae) to attach to, compared to other copper alloys. This reduces biofouling, which can severely degrade heat transfer efficiency.

3. Good Heat Transfer

While not as thermally conductive as pure copper or Admiralty brass (C44300), C68700 still offers very good heat transfer characteristics—enough to be highly effective in condenser and heat exchanger applications where its corrosion resistance is the overriding concern.

4. Good Strength and Fatigue Resistance

The addition of aluminum provides solid solution strengthening, giving C68700 higher tensile strength and better resistance to vibration-induced fatigue compared to simpler brasses like Admiralty. This contributes to longer tube life in high-flow, turbulent environments.

5. Cost-Effective for its Niche

Compared to more exotic materials like titanium or high-nickel alloys (e.g., Cupronickel 90/10 or 70/30), C68700 is significantly less expensive. It occupies a "sweet spot" where it provides dramatically better saltwater corrosion resistance than standard brasses at a reasonable cost premium.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!